Biogas

Transforming Biogas into Clean, Efficient Energy

At 2G Energy, we specialize in Combined Heat and Power (CHP) systems that turn biogas into a reliable, sustainable energy source. Whether you’re managing agricultural waste, wastewater treatment, or landfill gas, our CHP solutions empower you to maximize energy output while reducing carbon emissions.

Our biogas CHP systems are ideal for:

- Agricultural Operations: Use manure and crop residues to produce energy while managing waste.

- Wastewater Treatment Plants: Convert sewage gas into electricity and heat for plant operations.

- Landfills: Turn landfill gas into a profitable energy stream.

- Food and Beverage Industry: Recycle organic waste into energy for your facilities.

Our Biogas Solutions

g-box

50 - 60 kW

The g-box from 2G is an efficient and versatile small power plant offering an electrical output of 50 - 60 kW. Its connection-ready design and compact form make it ideal for applications like hotels, offices, and residential buildings. Key features include:

- Easy Integration: Connection-ready for seamless installation.

- Space-Saving Design: Minimal installation space required.

- Quiet Operation: Super-silent module with a noise level of max 55 dB(A) at 3 ft.

- Economic Performance: High thermal efficiency via condensing technology.

- Water-Cooled System: Eliminates the need for costly air duct installations.

- Reliable and Low-Maintenance: Built for high availability and durability.

- Versatility: Island mode and black start capability for enhanced functionality.

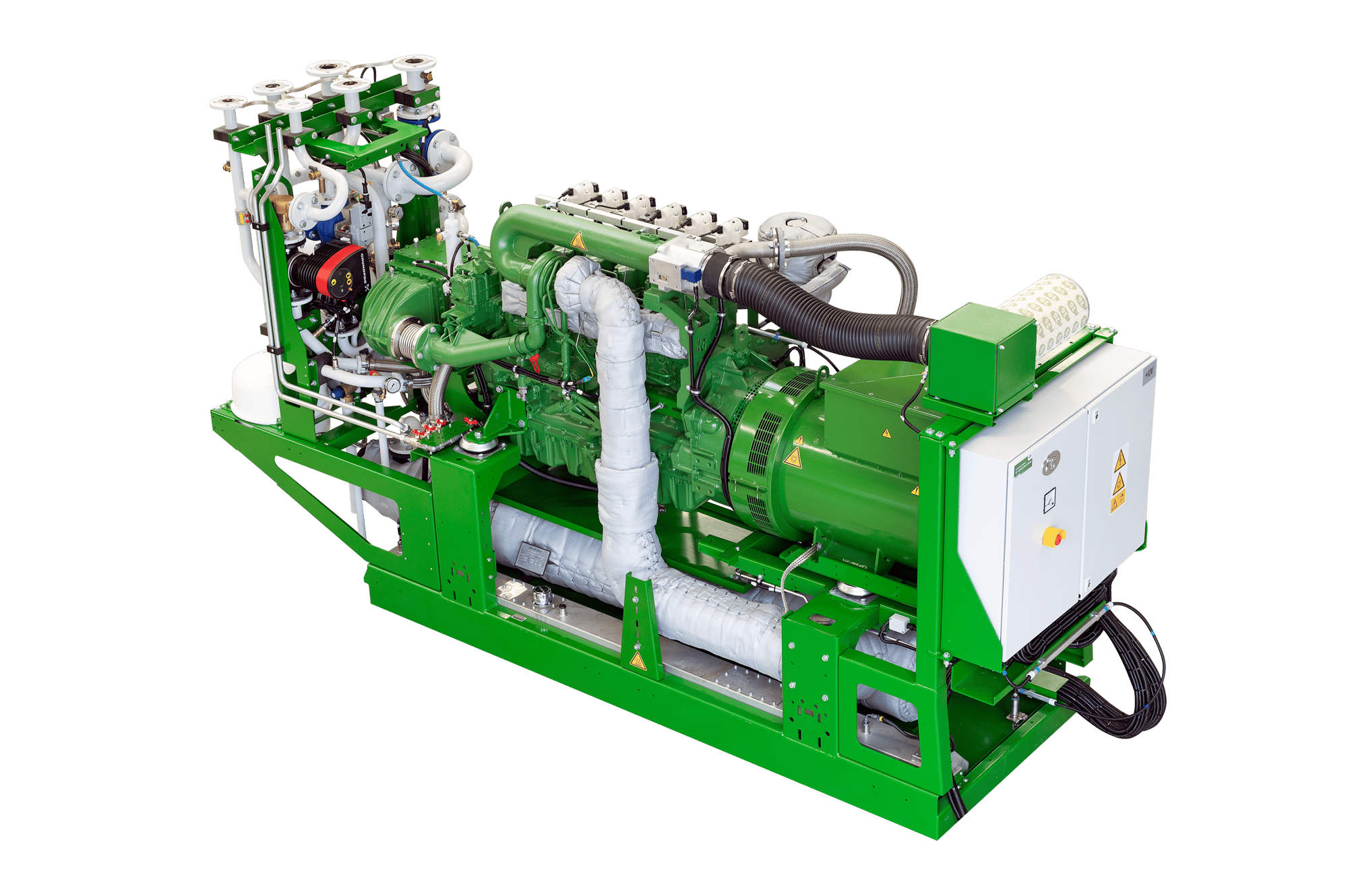

agenitor

80 - 450 kW

The agenitor by 2G results from extensive research and development efforts. It features optimized combustion chamber geometry that significantly enhances its efficiency.

- Optimized Performance: Advanced gas engine design for lower fuel costs.

- Compact & Modular: Easy installation, even in tight or hard-to-reach spaces.

- Reliable Operation: Durable, wear-resistant components for frequent start-stop use.

- Low-Maintenance: Built for long-term resilience and efficiency.

- Scalable Power: Twin pack configuration offers double the output

avus

550 - 2,500 kW

The avus by 2G is a highly efficient power plant designed for large-scale energy needs, delivering over 500 kW of electrical output. Ideal for industrial applications and microgrid supply, its modular design ensures all components are included for easy and seamless installation.

Scalable Power with Intelligent Control

- Expandable Output: Multiple units can be interconnected for higher electrical capacity.

- Intelligent Synchronization: A Master Control system supports synchronization and load sharing for up to 5 modules.

- Optimized Performance: Exceptional engine quality ensures efficient operation and extended running times.

Perfect for large-scale applications requiring scalable and reliable energy solutions.

Containerized Solutions

2G power plants offer flexible installation options tailored to local conditions and sound insulation needs. They can be integrated into existing structures or heating systems or independently housed in a container or engine room. With the right sound insulation package, noise levels can be reduced to as low as 35 dB (A) at a distance of 10 meters.

Compact Container

Sizes Available

Sizes Available

19.7 ft x 8 ft x 9.5 ft

Acoustic Emissions

Standard: 65 dB (A)

Super silent: up to 55 dB (A)

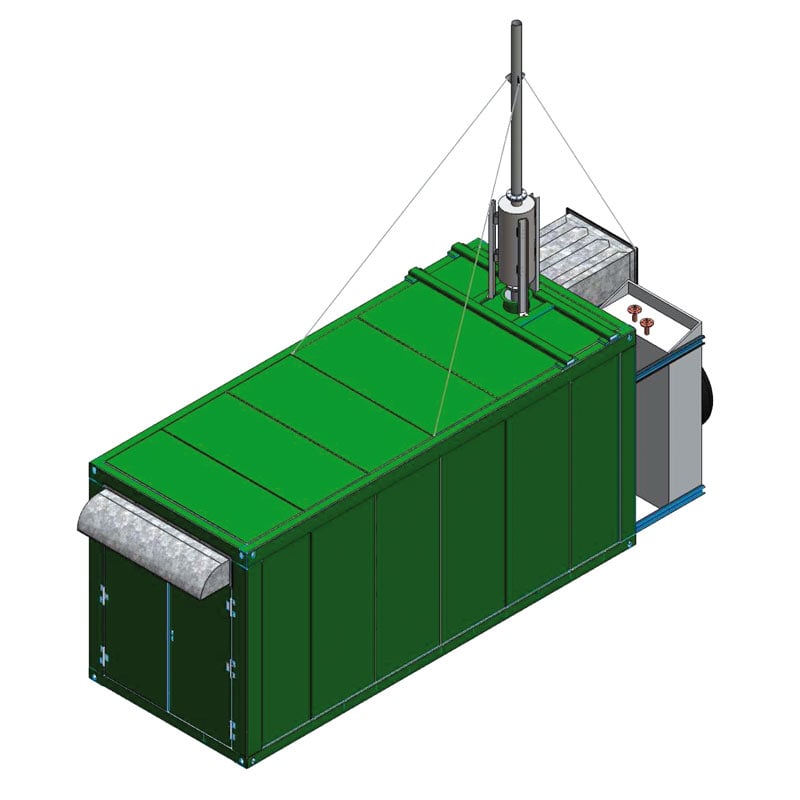

Standard Container

Sizes Available

Sizes Available

22.9 ft x 9.8 ft x 9.8 ft

31.5 ft x 9.8 ft x 9.8 ft

Acoustic Emissions

Standard: 65 dB (A)

Super silent: up to 52 dB (A)

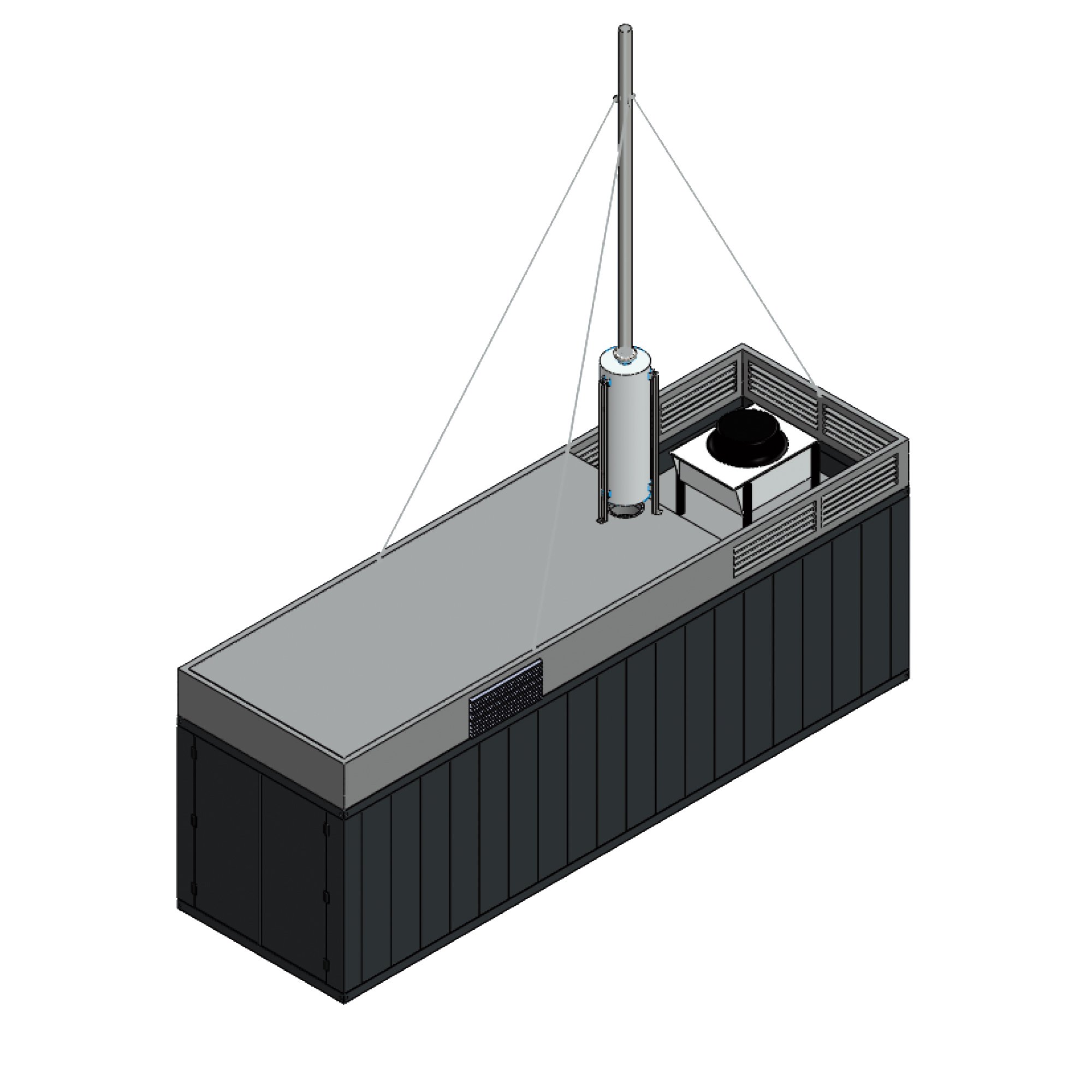

Highline Container

Sizes Available

Sizes Available

29.5 ft x 9.8 ft x 12.1 ft

34.4 ft x 9.8 ft x 12.1 ft

39.4 ft x 9.8 ft x 12.1 ft

39.4 ft x 14.1 ft x 17.5 ft

Acoustic Emissions

Standard: 65 dB (A)

Super silent: up to 45 dB (A)

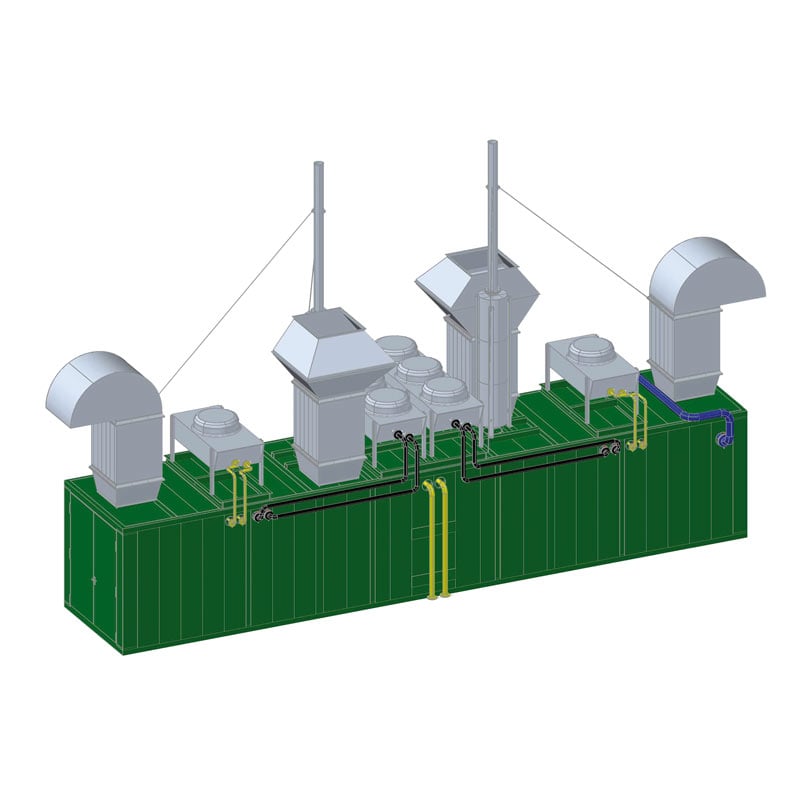

Twinpack Container

Sizes Available

42.7 ft x 9.8 ft x 9.8 ft

49.2 ft x 9.8 ft x 9.8 ft

Acoustic Emissions

Standard: 65 dB (A)

Super silent: up to 52 dB (A)

Heavy Container

Sizes Available

39.4 ft x 9.8 ft x 9.8 ft

49.2 ft x 9.8 ft x 9.8 ft

55.8 ft x 9.8 ft x 11.2 ft

Acoustic Emissions

Standard: 65 dB (A)

Super Silent: up to 52 dB (A)

Outdoor Sound Capsule

Sizes Available

Sizes Available

Depending on product

Acoustic Emissions

Standard: 65 dB (A)

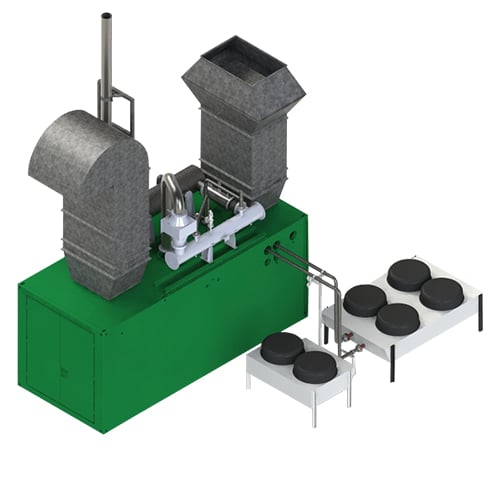

Sound Capsule

Sizes Available

Sizes Available

Depending on product

Acoustic Emissions

Standard: 65 dB (A)

Biogas Case Studies

Stanton Farms - London, Ontario, Canada

From how they cool the milk using a combination of earth energy and unique heat-exchange technology to converting on-farm organic waste to renewable energy to power up the neighboring community, Stanton Farms is always looking to close the loop in every aspect of their operation. Family-owned and operated by Laurie Stanton and his wife Sandy, along with their children Jeff, Jim, Greg, and Amy, Stanton Farms is the largest of six agricultural biogas facilities in Ontario. Stanton Farms has 2000 dairy cattle, including those used for dairy production and a genetics and breeding operation. Each cow generates 4 kW/day of renewable energy from the manure they produce.

DariTech - Tillamook, OR, USA

The Port of Tillamook Bay (POTB), a 1,600-acre industrial park on the Oregon coast, ordered a complete $5.6 million manure anaerobic digester from DARITECH, including a highly efficient 1.2 MW 2G avus biogas CHP system. The fully integrated prime mover of the CHP System is a 2G avus 1200 with an MWM core engine and a capacity of 1,200 ekW/h or 9,960 MW p.a. electrical power and 1,225 kWh of thermal power. In addition to the CHP unit, 2G Energy Inc. supplied the complete gas treatment, including a cooler, dryer/dehumidifier, and the H2S removal system.

Region of Waterloo Waste Water Treatment Plants - Ontario, Canada

The Region of Waterloo Waste Water Treatment Plant CHP sites has been active for many years. It is estimated that the anaerobic digesters at the existing WWTP in Waterloo alone produce 4,000 to 7,000 cubic meters (m3) of biogas daily. The electrical power produced is consumed within the WWTP's, offsetting power purchases to operate the plant. The heat produced by the engines is used to heat incoming sludge to the digesters and heat the digester buildings when required (mainly in the winter).